ATMA CHAMP. ENT. CORP.

Booth No.: K 28

Company Profile

ATMA has been cultivating deeply in screen printing equipment market more than 4 decades, and is sustained innovative research and development with prospective thinking, multi-stage development core technology maintains long term global competitiveness. Utility model patents are gained honorably in 32 countries, 170 Utility model patents has been gained and about 90 models are certified by Taiwan Excellence Award, long term promotion TQM total quality management won 23rd National Quality Award, and towards higher-level craft inheritance and higher-value product manufacturing.

Innovation is essentially growth. The changes in the industrial environment are increasingly intensified. In response to the trend of the times, ATMA has vigorously studied and synchronously developed new screen printing, inkjet printing technology & new energy in recent years.

Along with the progression of technology, four major innovative technologies as Big Data, Intelligentization, Mobile Internet and Cloud Computing, which are decisive victory in the era of intelligent technology, expected if this trend can be mastered to reverse traditional industry thinking mode, it can take the lead in this wave of intelligent technology revolution.

ATMA is striving for transformation and is based on the development process of Industry 4.0, fully automatic production lines is main stream. In addition, it is good time currently to fully expand the territory in market of 5G application, Automotive Touch Panel, Biotechnology medical, AI artificial intelligence and smart home.

Website: click

Products

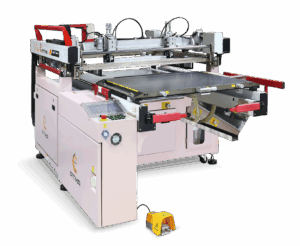

ATMAOE EW68TT

Dedicated to process screen printing photoimageable resistance solder mask wet film plug / non-plug-via on PCB.

Initiative double squeegee bidirectional printing + bidirectional peel-off + bidirectional table displacement and so on patented function, double machine operating, drying after both sides to be printed, precise control (circuits corner crack may not be left out printing), (bidirectional printing ink misaligned / precise), (auto cleaning residue ink beneath screen mesh), ( plug-via holes satiation, don’t bump after drying) and so on perfect printing effect, significantly increase printing speed and yield rate, leading the trend of PCB production mainstream

AT-EW80P

Dedicated to print photo-imaginable solder mask plug-via or non-plug-via wet-film process onto PCB.

Initial inventive double squeegee two ways printing + double peel-off + two ways table displacement and so on patented functionProcessed by two machines, drying after printing both sides, precisely control (circuits corner and crack are not left out printing), (two ways printing ink separately / precision), (automatic clean up residual ink beneath mesh), (fully plug-via and not bump after drying) and so on perfect printing effect, big increasing printing speed and yield rate to lead the trend to become main stream of PCB processing

ATMALINE PC68-SP

Specialized in multi-layer double sided PCB solder mask automatic screen printing line.

Allied with customer strategic R&D, enquiry for bespoke design was arranged immediately to understand production notion and layout planning, all function could be gathered, technical R&D was carried out right awayThis printing line is consisted of various units to attain fully automatic production efficiency, reduce manpower workload, also achieve purpose for energy saving (original process twice printing twice drying to improve twice printing one time drying.)

Crucial point is to make fixture for solder mask screen printing (C/S side) and CCD detects registration + auto turn over, also digital control servo screen micro adjustment to replace mechanical three point fine adjustment, assure smooth workflow, initiative invention fully automatic solder mask inline process.