Jiangsu Himonia Electronic Materials Co., Ltd

Booth No.: E 27

Company Profile

Haitian Ink – Dare to Be True

Since its establishment in 2010, Haitain Ink has focused on the development and application of photosensitive materials specifically for PCBs (Printed Circuit Boards). For over a decade, we have been committed to providing comprehensive solutions for the PCB solder mask process, earning an excellent market reputation in the domestic electronics industry and making outstanding contributions to the domestic substitution of key materials in China’s electronics industry.

Our Products and Services

Product Structure:

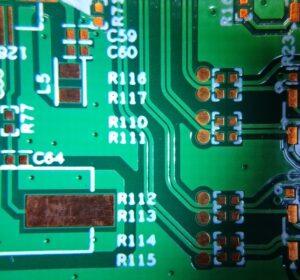

Our product line is rich and diverse, including solder mask inks, photo-sensitive plugging inks, lettering inks, plugging resins, and circuit inks, fully covering customer needs.

Application Fields:

Our products are widely used in various fields such as consumer electronics, automotive electronics, industrial control, AI servers, and aerospace, serving global well-known brands like Microsoft, Huawei, Lenovo, Schneider, and Xiaomi.

Customer Trust:

We have gained the long-term cooperation and trust of well-known domestic and international PCB manufacturing companies such as Unimicron, Wus Printed Circuit, Founder Technology, Xingchen Quick, and Jingwang Electronics.

Website: click

Products

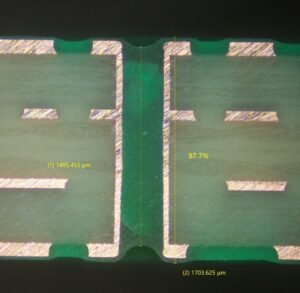

The products of the HSR-200 HP series of plugging inks are mainly photosensitive and developable type.

The products of the HSR-200 GK series of solder resist inks are mainly photosensitive and developable type.

1. Thermal Curing Solder Resist Ink: It is a two-component product containing VOC, consisting of a main agent and a hardening agent. Mix them together when in use.

Coating method: Dot-masking screen printing.

Curing method: Curing at a high temperature of 150°C for 60 minutes.

2. UV Curing Solder Resist Ink: It is a single-component product without VOC.

Coating method: Dot-masking screen printing.

Curing method: Curing by UV irradiation with an energy of 1000-2000 mj/cm².

3. Photosensitive and Developable Solder Resist Ink: It is a two-component product containing VOC, consisting of a main agent and a hardening agent. Mix them together when in use.

Coating methods: Screen printing, spraying, roll coating, inkjet printing.

Curing method: Pre-baking at a medium temperature of 70-80°C - UV exposure - development - post-baking at a high temperature of 150°C.

4. Inkjet Printing Solder Resist Ink: It is a single-component product without VOC, a liquid with ultra-low viscosity.

Coating method: Inkjet printing.

Curing method: UV curing + thermal curing.

The products such as the HSR-200 SW01 of character marking inks mainly adopt thermal curing and inkjet printing.