KE YAO MICRO-ELECTRONIC (HONG KONG) LIMITED

Booth No.: L 08

Company Profile

Jiangxi Keyao Equipment Co., Ltd., a subsidiary of Ke Yao Group, Hong Kong based company.

Dongguan Keyao Equipment Co. Ltd. was established in July 2003. To fulfil market expansion, Jiangxi Keyao Equipment Co., Ltd. was established in September 2021 in Longnan City, Jiangxi Province, with registered capital at HKD 200 million, it covers area of 60 acres, With R&D technology as its core, Jiangxi Keyao continuously innovates and develops automation equipment, realize industrial intelligence to fulfil market needs. In the future, Keyao Equipment Co., Ltd. will continue to innovate and optimize based on existing technology to adapt market changes and meet customer needs and achieve the company’s sustainable development.

江西科耀设备有限公司是香港科耀集团的子公司。

东莞科耀机电设备有限公司,2003年7月注册成立。因配合市场扩展需要 ,江西科耀设备有限公司于2021年9月在江西省龙南市注册成立,注册资本2亿港币,占地60亩

公司以研发技术为核心,不断创新开发迎合市场需求的自动化专用设备,实现工业智能化。未来,科耀机电设备有限公司将在现有技术的基础上持续进行创新和优化,以适应市场的变化和满足客户的需求,实现公司的可持续发展。

Website: click

Products

Laser Drill + Loader & Unloader(激光钻孔机 + 全自动收放板机)

【DataCom Production Executive System】 and 【AGV Logistic System】 could assist Mitsubishi double-table CO2 laser drilling machine equipped with a flip function automatic loader and unloader, ultra-high performance on laser drilling, reduce the pollution caused by manual operation, avoid manual errors, and achieve continuous production. The System has a two-boards sensing function, a QR code reader to improve production efficiency.

日本三菱双台面CO2激光打孔机,超高性能的激光钻孔。【全自动收放板机】设有翻板功能,配合【DataCom 生产执行系统】广告牌及【AGV物流系统】,可减少人手操作对板造成的污染,避免人手失误,可达致连续生产;设有两片板感应功能,增加二维码读码器,提高生产效率。

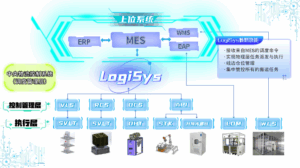

LogiSys – Smart Logistics System (LogiSys 智能车间物流管理系统)

LogiSys is a one-stop integrated solution for managing resources of the facilities and/or equipment to have the best logistic performance. The system would maximize the logistic mechanism and resources allocations, to have highly efficient smart logistics system.

LogiSys 提供一站式整合方案,针对智能车间物流对厂内不同设施或设备控制及资源管理。解决上位系统对自动化物流的机动性及资源分配,打造更高效厂内智能化物流系统。

Datacom Intelligent Automation Production System(Datacom智能自动化生产系统)

DataCom consists of multiple subsystems, each of which can operate independently.

The system allows for data integration and interoperability with third-party platforms.

A fully customized and exclusive production execution system can be built progressively according to customer requirements.

DataCom涵盖多种子系统,每一种子系统可单独使用,也可以开发数据对接到其他系统,可根据客户需求逐步构建定制化专属生产系统。