Yan Tin Chemicals Co., Ltd.

Booth No.: K 31

Company Profile

YAN TIN CHEMICALS CO. LTD., our head-office founded in Hong Kong in 1984. We have been engaging in developing chemical manufacturing products and acting as agent of brand name materials from different countries. These products are mainly supplied for the circuit board manufacturer and electronic component assembly. We always provides variety service to different kinds of customer.

Now, we are employing over 500 employees. Starting from the year of 2003, our business has been extended to other foreign countries like, Thailand, Vietnam, US and Europe.With our mission of customer first, we are confident in providing satisfactory service and best product to our customer. And, it is exactly our reasonable price, quality services and products that contribute to the friendly-partners relationship between our customer and us. We have certified as ISO 9001 and ISO14001; and being supported by society.

Website: click

Products

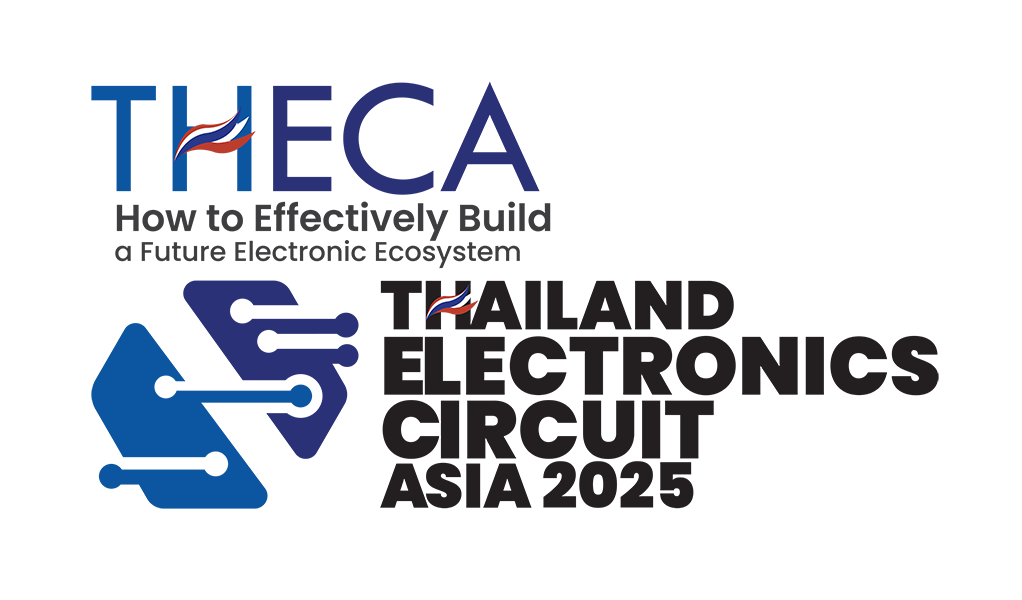

DRY FILM PHOTORESIST ADC-253 For HDI

1. AW-2503 for normal & wet lamination 1.ADC-253 excellent resolution and adhesion with i-line / h-line.

2. ADC-253 good adhesion and conformity in凹凸 on copper surface.

3.ADC-253 good conformity helps to get higher yield by reducing open / nick.

4.AW-2503 excellent resolution and adhesion with conformity.

5.AW-2503 has excellent performance in wet lamination that helps high efficiency and yield.

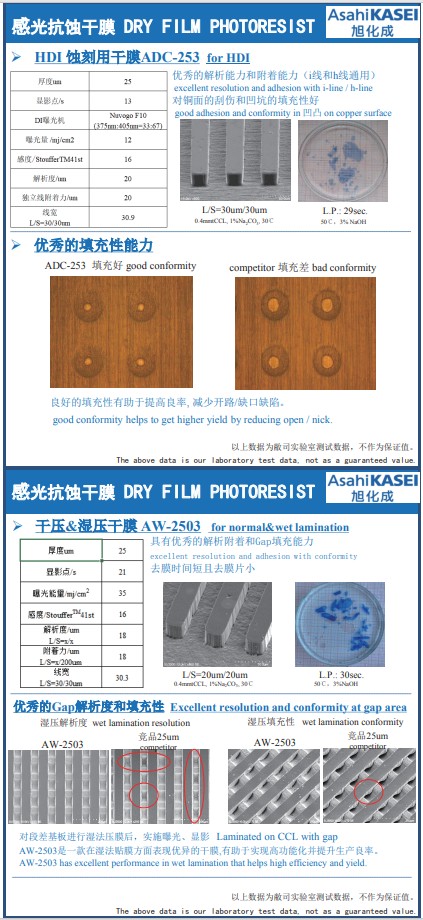

Glicap; OSP-F3 & Microetching chemicals

1. Glicap---Chemical Adhesion Process Excellent chemical adhesion with various materials without roughening copper surface.

2. OSP-F3 (High reliability OSP) It shows excellent performance in terms of copper oxidation and humidity protection for longer shelf life, because of higher density organic layer than conventional OSPs.

3. Microetching chemical- Pretreatment for Dry film: Glibrite™ GB-3100 series. Pretreatment for Solder resist: Glibrite™ GB-4300 series. Microetching chemical for galvanic effect: Glibrite™ GB-1400 series. Excellent chlorine resistance, tap water and industrial water can be used.: Glibrite™ GB-200 series.

Auto-Cut Laminator

1. Two lamination rollers system, improved adaptability and adhesion strength.

2.Synchronized moving and cutting system.

3.Aluminum skeleton for facilitating maintenance.

4.Easy to operate through touch panel.

5.Rear Conveyor using a magnetic driver. Reduce particle contamination of the copper plate.

6.Rear Conveyor can be turned on to facilitate maintenance operations.

7.Multiple languages interface can be selected.